Space And Materiality Week 12-14

I decided to make this one proper blog instead of splitting it weekwise since doing the latter would completely break the flow of our process!

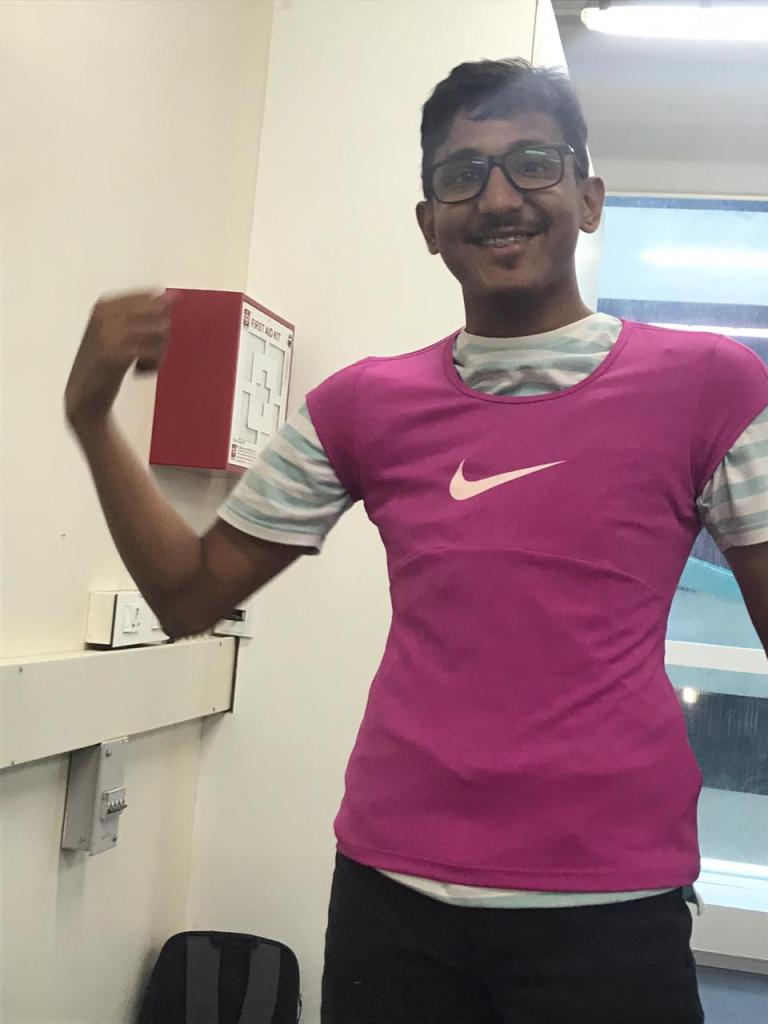

Since we were paired together for this project,Murtaza and I knew what our strengths and weaknesses were,academically.I’m better at conceptualizing and sketching,while he’s better with the physical work and execution.But both our brains work the same and so thankfully,we can play off of each other’s thoughts till we come to a consensus.We had made it pretty clear that while I will help for the first half of the project,Murtaza will take charge in the second half.An (almost) fair distribution of who does what.So he has primarily been responsible for making the concepts I decided into a usable reality.

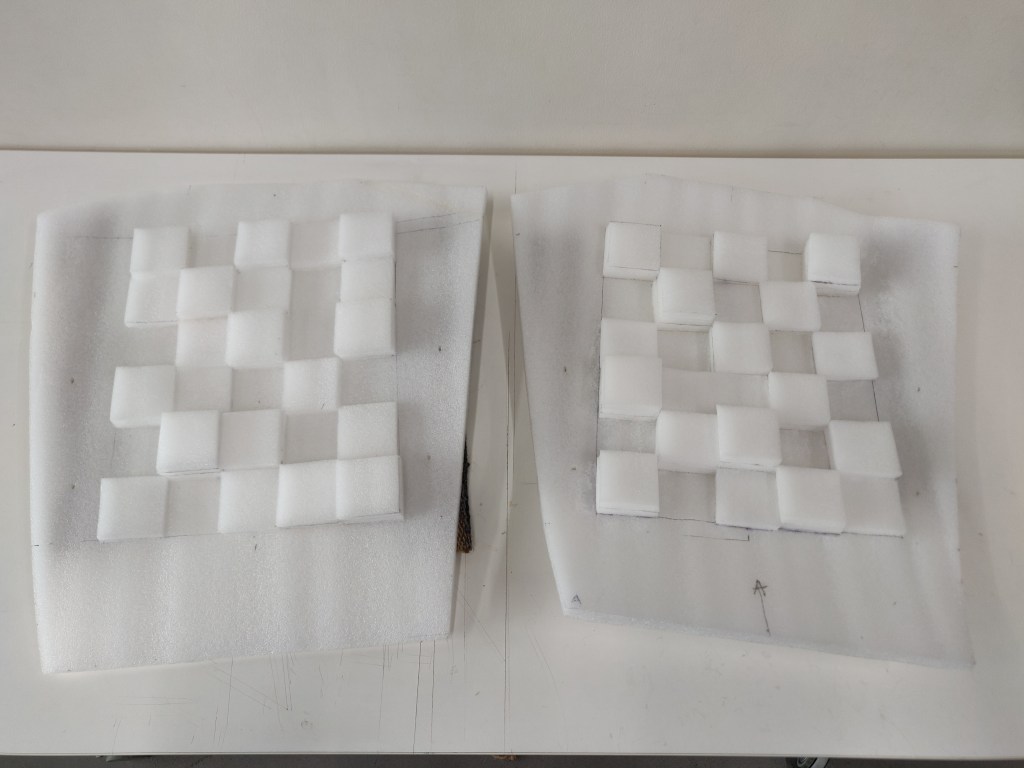

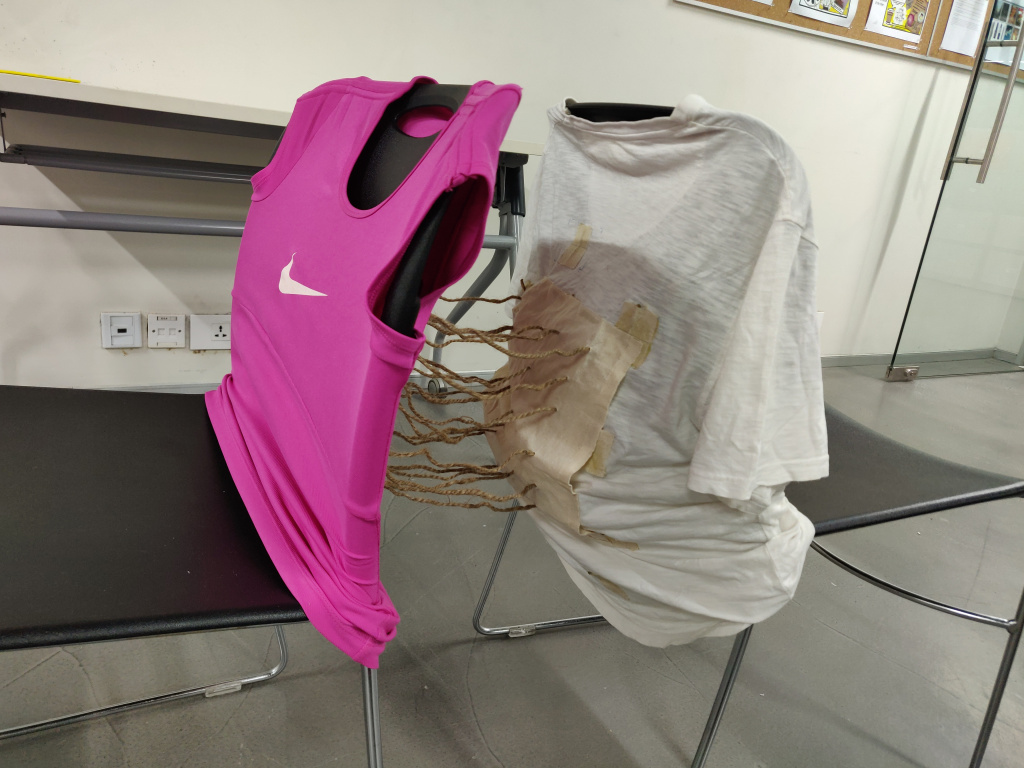

We were pretty clear that we wanted to spear no expense for our wearables to be sturdy and firm,starting right from the prototypes.We’d heard of and seen enough prototypes snapping into two immediately or failing miserably over and over again,so we thought,why not start off like our prototype itself can be used as a final?(Spoiler alert: This thought was really useful later.)

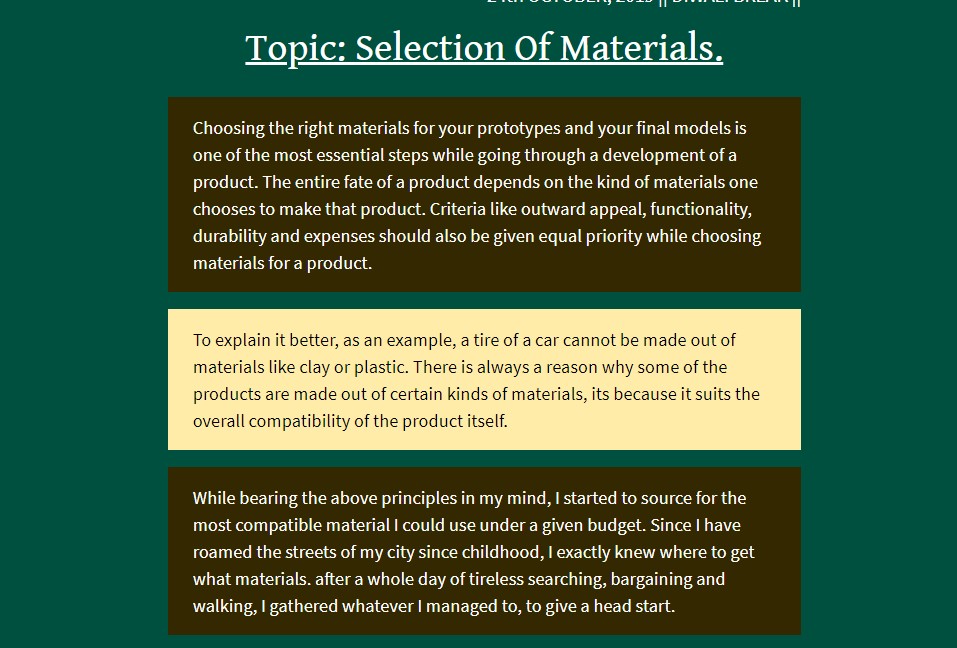

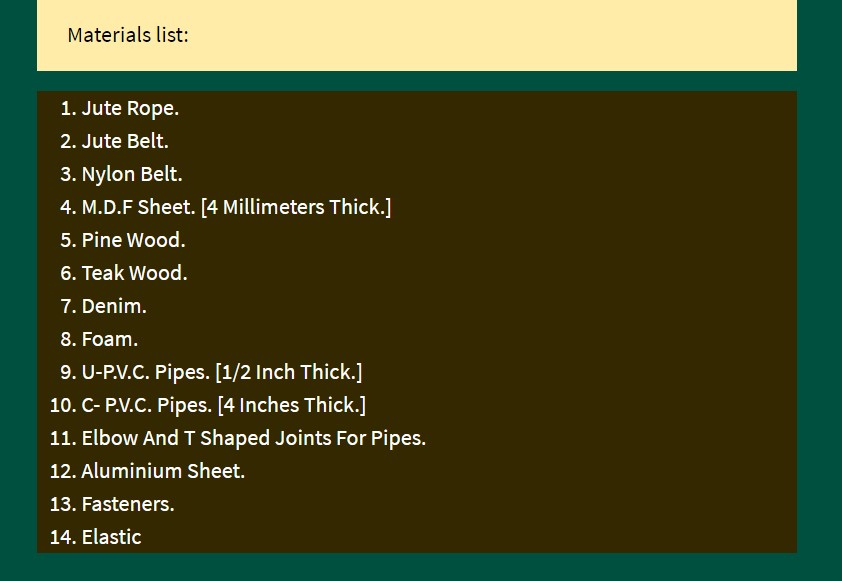

So he went on his usual adventure to find the toughest items possible in the cheapest prices possible(later racking up quite a bill),and by the beginning of week 12 we had quite a few things to play with.Below are a few snapshots from Murtaza’s blog,describing his said adventure through markets and the materials he managed to find.

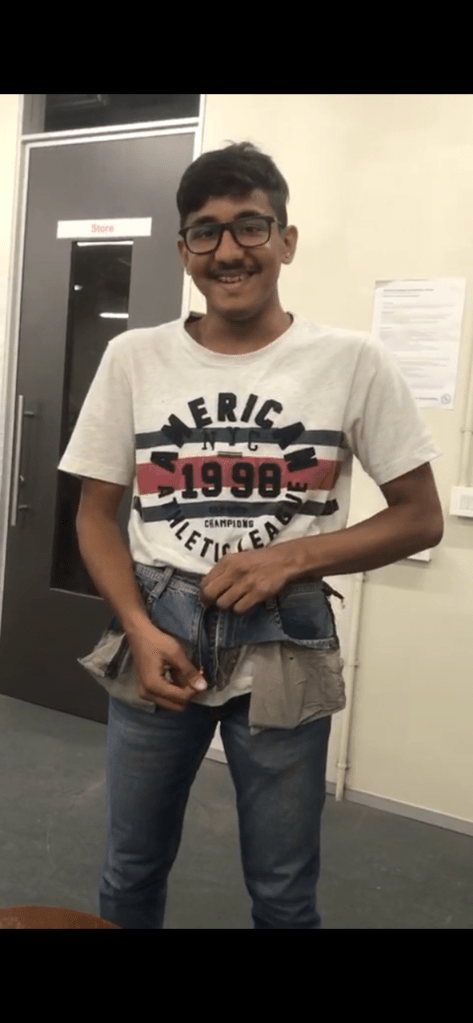

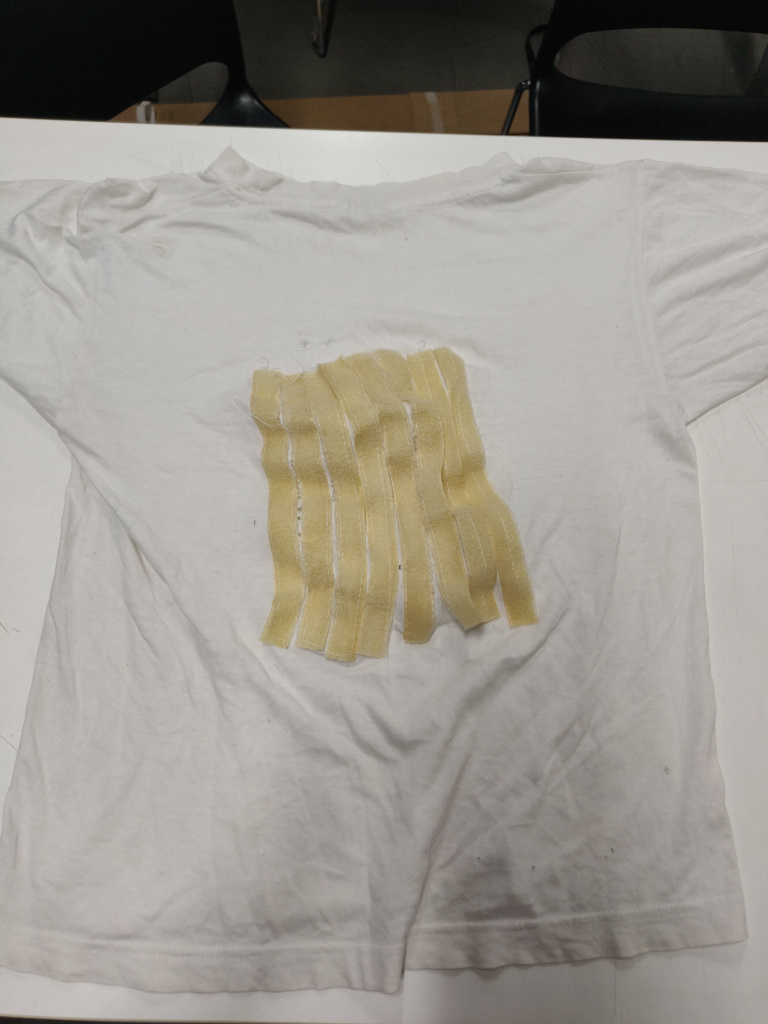

We then slowly began making our prototypes,being in no hurry since we knew that these were probably more important than the final models.These are a few of them:

It almost looked like a proper shoe.

The pulling of the strings works perfectly to tighten around the knee and bring both knees closer.

Those were a glimpse of what our prototypes looked like along week 14.We were sick of our classmates tormenting us, asking,”is this your final??no???” over and over again!But that just meant our prototypes were that solid.These are just a gallery of photos,but they took an insane amount of effort to accomplish,especially on Murtaza’s part.I helped out with the donkey tasks,like cutting,sanding,measuring,and sticking,but it all came together after he put in his work.Here’s some memories over these three weeks,of how our prototyping process slowly unfolded:

After all this was over,we had to start gearing up for our final.As our prototypes are life size,sturdy models,the only thing different that we could do for the finals was change up the material choice.More of that in the next blog!

Meanwhile,I’d recommend checking on my partner’s blog simultaneously with mine.We agreed to work in collaboration on our blog,so they make sense if viewed together!